densité de flux et relation de champ

-

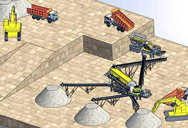

broyeurs à ciment calcaire

-

mobile concasseur à mâchoires à vendre en afrique du sud

-

le minerai de fer de concassage screeing chine

-

le coût de la machine de broyage d'impulsions

-

souper de poudre de dolomite broyage fin importateurs de la france en allemand

-

station de concasseur de roche mobiles

Vibratory Feeders in the Manufacturing Industry

2020.10.22 Vibratory feeding and conveying equipment has been used in the manufacturing industry for several decades to move fine and

Bavarder sur Internet

Designing vibratory linear feeders through an inverse

2017.8.25 to the feeder to be designed. The experimental develop-ment of the

Bavarder sur Internet

Dynamic analysis of vibratory feeder and their effect on feed

2017.4.1 The vibratory feeder is a forced vibrating system mostly used in industries

Bavarder sur Internet

Structure Optimization of Vibrating Feeder Based

2021.1.30 Vibrating feeder is a kind of feeding equipment widely used in metallurgy, coal, electric power, and chemical industries. It is used

Bavarder sur Internet

GF Vibrating Feeder-SBM Industrial Technology

2023.10.26 GF Vibrating Feeder. GF Vibrating Feeder is the grizzly feeder driven by the vibrating motor. As an efficient primary feeder, it is specially designed for mobile crushing stations (also known as mobile

Bavarder sur Internet

Vibrating Feeder – Industrial Vibrating Feeder AGICO Cement

The vibrating feeder used in stone crushing plant and cement plant is also called

Bavarder sur Internet

Feeders and Vibrating Conveyors - Springer

2017.8.27 Feeders are short conveyors or other devices used to take material from

Bavarder sur Internet

Vibrating feeder - All industrial manufacturers

A vibrating feeder is equipment tasked with transferring between two equipment in a bulk material process. Feeders of various sizes and types are used for continuous feeding of crushers ...

Bavarder sur Internet

DEM Study of the design parameters of a linear vibratory feeder

2023.5.3 Vibratory feeders are vastly used in a variety of applications such as

Bavarder sur Internet

Compact Feeders CONVEYING AND FEEDING BULK

2021.8.19 Using this controller and an integrated vibration distance adjuster, the flowrate can be freely adjusted within wide limits. AViTEQ compact feeders do not disturb the peace – they stand on rubber buffers, so the vibration only has an effect on the conveyed materials and is hardly noticeable in the surroundings.

Bavarder sur Internet

Typical construction of a vibratory feeder

Normally, a vibratory bowl feeder is driven by an electromagnetic or piezoelectric bimorph at a sub-resonance frequency to attain a resonance vibration to transport the parts. It has the ...

Bavarder sur Internet

Materials Free Full-Text Vibratory Powder Feeding for

2021.6.25 Measured feeder displacement amplitude versus frequency for both Ti-6Al-4V and Fe-Ni powders when the imposed vibration amplitude of the voice coil was fixed as constant. Additionally, plotted as a solid line is the predicted behavior assuming the feeder/voice coil system as a driven, damped harmonic oscillator.

Bavarder sur Internet

Vibratory Bowl Feeder: Definition and Applications - Bellco Feeders

2023.1.11 Fundamentally, a vibratory feeder bowl consists of a bowl-shaped container with spiral tracks positioned inside. In the first stage of the process, parts are loaded into the bowl from a bulk container and shaken by vibration sequences to move them up through the tracks. Components will gradually align themselves as they move forward

Bavarder sur Internet

Feeding systems: vibrating bowl feeder, conveyor, hopper

2019.2.28 The centrifugal feeder is a system for high-speed feeding (up to 1000 parts/min) of the subsequent workstations such as assembly, control or packaging machines. Silent and vibration free, our centrifugal feeders are particularly designed to distribute and guide fragile and small parts in plastic, rubber or metal.

Bavarder sur Internet

VIBRO FEEDER – WORKING PRINCIPLE AND APPLICATION

Vibro Feeder is the equipment used for feeding material to conveyors or other machines. It uses vibration to move the material in the feeder. Unbalanced Motor or Electromagnetic vibrator generate vibrations. A vibratory feeder is used in many various industries for automatic feeding from small to large quantities of feeding.

Bavarder sur Internet

Dynamic analysis of vibratory feeder and their effect on feed

2017.4.1 The damping characteristics depend on the mass of the material on the feeder trough, the type of material and the vibration amplitude. The experiments showed that at higher amplitudes of vibrating trough, the material being conveyed on it reacts with higher damping values as much as 0.1, whereas the trough vibrating with lower amplitude

Bavarder sur Internet

Flexible Vibrating Feeder for Parts from 3 to 15 mm - Asyril

2022.10.6 Feeder Advantages Compatible with all part geometries: 99% of parts can be fed on our feeders - including complex geometries and delicate materials Extremely gentle part handling due to Asyril’s innovative 3-axis vibration technology: parts can be moved in all directions, including the optimal choice of flipping amplitude for each part.

Bavarder sur Internet

Vibrating feeder - All industrial manufacturers

vibrating feeder. electromechanical motorized for bulk materials. The RF series manufactured by Tarnos, is an electromechanical vibratory feeder that runs on a 90 - 650 t/h. It features a low power electric motor that is

Bavarder sur Internet

General Science Introduction of the Vibrating Feeder-CSDN

2019.9.22 1, vibration stable , works reliable. 2, special trash rack design to prevent material clogging. 3 . adjustable trash rack gap. 4, more wearable pieces. 5, for preventing the wear parts be wored by the small materials, small material should be separated to increase production. Optional frequency motor can be stalled to adjust the frequency ...

Bavarder sur Internet

(PDF) Design and characteristic analysis of vibration feeding

2020.12.18 A vibration feeder is a piece of equipment for rationing and conveying powder, particle and block materials. In order to test the regeneration performance of de-dusting medium for high-temperature ...

Bavarder sur Internet

Feeder - China Vibrating Feeder, Poultry Equipment

Automatic Bolt Screw Nail Nut Vibratory Bowl Feeder for Assembly Line. Featured Product. FOB Price: US $1800 / Piece. Min. Order: 1 Piece. Dongguan Chuanghui Automation Co., Ltd. is a branch of Keepro Industry Group, founded in 2009 and specialized in developing and producing various high quality automatic ...

Bavarder sur Internet

(PDF) Vibratory Powder Feeding for Powder Bed Additive

2021.6.25 amplitude, the feeder oscillates, but no powder is seen to leave the feeder. Materials 2021 , 14 , 3548 12 of 19 Materials 2021 , 14 , x FOR PEER REVIEW 12 of 19

Bavarder sur Internet

Vibratory Feeder Mineral Automatic Feed - JXSC Machine

2023.11.9 Vibratory Feeder. JXSC’s Vibrating Feeder is an instrument that uses vibration to “feed” material to a process or machine. Our vibratory feeders use vibration and gravity to move material: Gravity determines the direction, either down or down and to a side, and then vibration is used to move the material. [Capacity] 96-560 T/H.

Bavarder sur Internet

Vibratory Feeders in the Manufacturing Industry - SME

2020.10.22 Vibratory Feeders in the Manufacturing Industry. Vibratory feeding and conveying equipment has been used in the manufacturing industry for several decades to move fine and coarse materials into mixers, furnaces, production processes or final containers. Compact feeders can convey raw or moist product like cheese during a food

Bavarder sur Internet

Vibrating Feeders: How They Work and Effectiveness

2023.5.18 Vibrating Feeders: How They Work and Effectiveness. Newton’s First Law is the backbone of vibratory feeders. Contingent on the laws of physics, an object must first be in motion to stay in motion. A vibratory feeder is an instrument that uses vibration to feed material through a process or a machine while controlling the rate of flow.

Bavarder sur Internet

Articles liés

- Concasseur à mâchoires Cedar Rapids 10x24

- broyeur de la bouillie de l 039 eau de Calcite de houille

- charbon de la mine de deversement acheter les tapis

- la taille de l'entree la taille avant d'ecraser

- traitement du charbon à makomo

- perushahaan de concasseur

- Concasseur De Pierre Electrique De 75 Ch

- mines de grès dans le Gujarat

- ironore machine de concassage au RoyaumeUni

- canettes en aluminium de broyage pour le recyclage

- concasseur à cône concerne

- venta de molino triturador

- tube procédé de pressage

- usine de concassage de granit pour vente au nigéria

- atta chakki machine

- marteau raison de concasseur

- informations sur la double concasseur à percussion

- broyeur de pierres et de plantes de carrière à aveiro portugal

- fabricant de convoyeur de convoyeur de concasseur en malaisie

- fabricants de machines industrielles à concassage de pierres

- la philosophie de contr le de circuit ferme broyeur a ciment

- usine de traitement des résidus miniers

- broyeur à rouleaux beban

- raymond broyeur allemagne inde

- fabricants de mobilier en fer forgé plein air

- tete de broyage pour mini pelle

- fabricant de broyeurs a marteaux en Inde vsi d'armes de l'armee

- télécharger fer katalog usine de minerai de concasseur

- concasseur à mâchoires fenner

- utilisé jaw prix de concasseur