Fabricants de charbon de concassage en Inde

-

les petits fabricants des usines de pulverisateur en Inde

-

fabricant de rectification de rouleau ondulé

-

petits moulins de timbre

-

axe vertical concasseur rotor

-

specifaction de tamis vibrant

-

bangladesh siege de soupape machine de coupe

The extraction of vanadium from titanomagnetites and

2020.1.15 The chemistry of vanadium extraction from vanadium-rich slag by the salt roast/water leach process is quite similar to that involved when processing ores and

Bavarder sur Internet

Vanadium properties, toxicity, mineral sources and extraction

2022.1.4 Vanadium properties, toxicity, mineral sources and extraction methods: a review SpringerLink. The toughness and tensile strength of the steels are significantly

Bavarder sur Internet

Extraction of vanadium from V-containing titanoferrous

2021.1.1 The design of vanadium extraction processes also considers the initial chemical additives for either alkali or acid treatments. Alkali treatments are classified into

Bavarder sur Internet

A Comparative Study of Extracting Vanadium from Vanadium

2022.5.3 In this study, a new vanadium extraction process from vanadium titano-magnetite(VTM) featuring calcification roasting and (NH 4) 2 C 2 O 4 solution leaching

Bavarder sur Internet

A critical review on extraction and refining of vanadium

2021.12.1 Extraction Refining 1. Introduction Vanadium is a refractory metal (melting point 1890 °C), which belongs to group VB in the periodic table of elements with

Bavarder sur Internet

Extracting vanadium pentoxide from minerals and

2021.1.1 Vanadium-extraction technology includes three approaches, where vanadium pentoxide is extracted from: low-grade raw materials, high-vanadium raw

Bavarder sur Internet

A Method to Extract Vanadium from HIsmelt Reduction Slag: In

2023.4.28 The vanadium titanomagnetite (VTM) ore is a special type of iron ore that contains not only iron oxides but also significant amount of vanadium (0.5–3 wt.% as in

Bavarder sur Internet

Theoretical Modeling and Experimental Evaluation of Vanadium

2023.11.3 Recovering vanadium from vanadium titanium-magnetite (VTM) ore using (NH 4) 2 C 2 O 4 is a clean hydrometallurgical process, but the drawback is the low

Bavarder sur Internet

The extraction of vanadium from titanomagnetites and other

2020.1.15 Vanadium is usually extracted from ores, concentrates and slags by roasting with sodium carbonate or another sodium salt to convert vanadium into water

Bavarder sur Internet

Articles liés

- sable des technique de broyage de silice

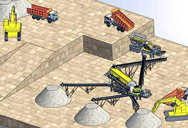

- ligne de production de concassage de fer en inde

- bandes transporteuses information et des ressources

- de cluster de minerai de fer

- prix de machine a chaussette algerieEquipement de Concassage

- concasseur de ciment en maroc

- concasseur à marteaux de mica

- pequena trituradora ofrece

- Machine De Concasseur De Granit D Allemagne

- vendeur et fabricant de broyeur de plastique en algerie

- dresser des pierres dans des blocs

- quartz station de concassage argentine

- broyeur de pierres pour le pakistan miniere

- des mécanismes de la ligne pierre de granit de ncassage shanghai

- l'équipement pour la bauxite

- harga concasseur à mâchoires batu kap 50ton confiture

- quel vitesse de cardan pour un broyeur avec un micro tracteur

- impact concasseur pfw la

- navajas de trituradora de mineria

- conception de structure de chargeur de vibration

- liming machines de fraisage

- broyeur vertical de ciment 200 220 tonnes

- molino para triturar barita

- tamis de semences industrielles

- pièces de concasseur sysmon

- de trituración de grava con trituradora de impacto

- ligne de production de granulats

- inconvenients du broyeur de pierre

- cot de machine de broyage de roche

- faja quebare donde mprar en venezuela