fabricants de moulin billes en inde gb

-

statue en pierre de ganesh

-

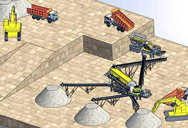

ensemble de meulage machine machinex

-

concasseur utilisé pour la vente

-

concasseur à machoires mobile sur chenilles

-

pièces buccales des broyeurs

-

ventes de machines de broyage de marbre a bahrein

Study on the impacts of media shapes on the

2020.10.1 Effects of grinding media shape on the Mill power draw, Toe positions, and Shoulder positions (Mill diameter = 0.54 m, Mill length = 0.1 m, and J = 25%), DEM simulations performed by Kiangi et al. (2013).

Bavarder sur Internet

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL

7.2.1 Industrial mill media distribution ... 7.2.2 Load behaviour and mill power as affected by media shape .....110 7.2.3 Effect of media shape on breakage functions.....111 7.3

Bavarder sur Internet

Effect of grinding media on the milling efficiency of a ball mill - Srce

The size of grinding media is the primary factor that afects the overall milling eficiency of a ball mill (e.g. power con- sumption and particle size breakage). This article tackles the

Bavarder sur Internet

Ball charge loading - Impact of specific power ... - ResearchGate

2006.5.9 This paper examines the effects of changing mill filling degree with respect to specific power consumption (kWh/ton) and product throughput as well as the impacts

Bavarder sur Internet

(PDF) Mechanical activation of cement in stirred media mill

2013.2.1 It was found, based on the experimental results, that there is a mechanochemical effect on crystal structure of cement, mostly in the stirred media mill,

Bavarder sur Internet

Optimization of continuous ball mills used for finish-grinding of ...

2004.12.10 The results of extensive investigations carried out on industrial semi-finish-grinding plants indicated that the specific power consumption of the ball mill could

Bavarder sur Internet

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

liners and grinding media. The cost of optimization is minimal since inspecting the mill and the resulting modifications -- such as re-grading the grinding media or moving the

Bavarder sur Internet

Study on the impacts of media shapes on the performance of

2020.10.1 It was observed that grinding media shape (spherical, eclipsoids, cube, cylpebs, etc) can influence the performance of a tumbling mill. The media can directly

Bavarder sur Internet

Ball motion, axial segregation and power consumption in a full

2009.8.1 Fig. 5 shows the distribution of media and its flow in the first chamber of the cement mill. The feed end is towards the viewer and the cylindrical opening is where the

Bavarder sur Internet

Reducing energy consumption of a raw mill in cement industry

2012.6.1 The data collected over a 12-month period indicate that first and second law efficiencies of the raw mill increase as the ambient temperature increase and the

Bavarder sur Internet

Articles liés

- Travaux De Concassage De Calcaire

- granding machine liste des prix des produits dans la porcelaine

- meulage de précision entreprise

- anneau vertical et broyeur à boulets de broyage

- fabricant de flash de bannière

- primaire concasseur informations

- CoûT De Logiciel De Gestion De Concasseur En Inde

- chancadora de cantera con la norma ISO

- dessin du broyeur de minerai de fer

- cambodia société de vente de convoyeur à bande

- concasseur à mâchoires selon

- prix du cuivre au kilo decembre2014

- thaïland pierre concasseur

- Cylindre de broyage Terminer

- kaolin cout de concasseur amende

- machine utilisée pour le coke et le charbon

- concasseur de minerai de fer fabricants inde

- otsuka concasseurs à cônes pièces

- broyeurs billes dans lindustrie du ciment

- pew concasseur à mâchoires gulin

- wmf verre ceramill info moulin à épices

- sales representative roche source

- processus de sable artificielle de la production

- l'optimisation de la charge de la balle dans les utilisés de broyage du ciment

- broyeur d r sud afrique

- pierre buisnesses concasseur fabricants

- operation du four à la chaux et à la dolomie

- philippines de broyeur de znith

- dimensions et dessins des petits appareils de levage

- thrommel et broyeurs à boulets images